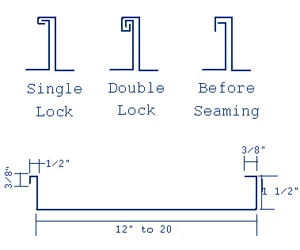

Double Lock

The standing seam system utilizes state of the art technology for roof integrity and positive weather-tightness. The seamed panel has been extensively tested in both steel and aluminum and meets the stringent requirements of the "Standard Structural Performance of SSMRS by Uniform Static Air Pressure Difference". Seams require machine closing, by either hand or power seamers, both available on a job rental basis. The seaming process completely encloses and seals all clips and fasteners for the most watertight seal available. The double lock 1.5" panel, in addition to the standard 90-degree seam, can be double-locked to obtain a 180-degree architectural profile. The standing seam system is especially suitable where roof slopes are low and unusually long panels are required. Available in various gauges of galvanized steel, galvvalume, aluminum, copper, and stainless steel. Regardless of which material is selected, the optional stiffeningribs or striations are highly recommended in order to reduce the slight surface waviness of the metal know as "oil-canning." Note: "Oil-canning is a natural phenomenon inherent in sheet metal products and therefore is not the cause for rejection of the material.

Snap Lock

Snap Lock offers the ultimate in standing seam metal roofing. Panel profiles are available in widths from 12" to 20". Each panel is directly fastened along one side in preslotted holes for a clipless installation. The adjoining panel locks over the screw flange completely concealing the fasteners. The 1" high seams are roll-formed on-site for roofs of nay length and pitches as little as three on twelve inches. Snap Lock provides a maintenance and worry free roof system without sacrificing beauty.

- 1" snap seam with the slotted flange for clipless installation

- No seaming necessaryAvailable in 24 and 26 gauge

- A maintenance and worry free roof system

- Variety of colors to choose from

- Custom flashing to fit your project

- Job-site technical support available

- On-site rollforming for continuous lengths